ROYAL FACADE

Facade Thermal Panels for Home Insulation from the Manufacturer

Clinker Thermal Panels: Manufacturing Technology & Key Product Characteristics

Quality thermal boards from Royal Facade™ are called a ready-made solution for cladding any building.

Americans are actively interested in the unique opportunity to simultaneously decorate and insulate the facade part of buildings. Therefore, they are considering the option of using special panels, whose operational efficiency has been proven in practice multiple times.

- Facade Insulation

- The facade receives reliable protection from negative environmental impacts and possible mechanical damage.

- Thanks to diverse facade designs and color shades, every building can be designed according to a pre-planned style and exterior features.

- ROYAL FACADE

Facade Thermal Insulation Boards: What Are They?

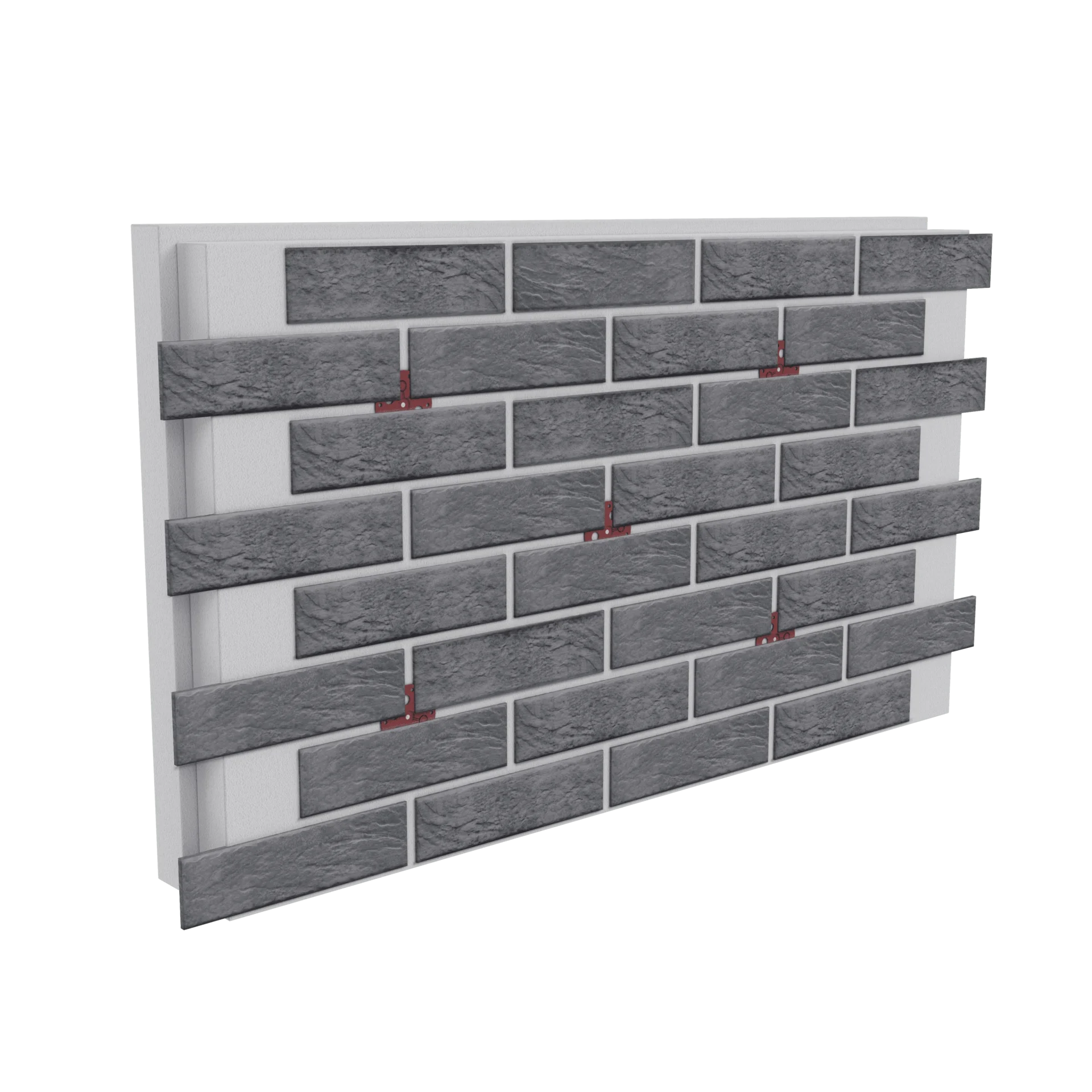

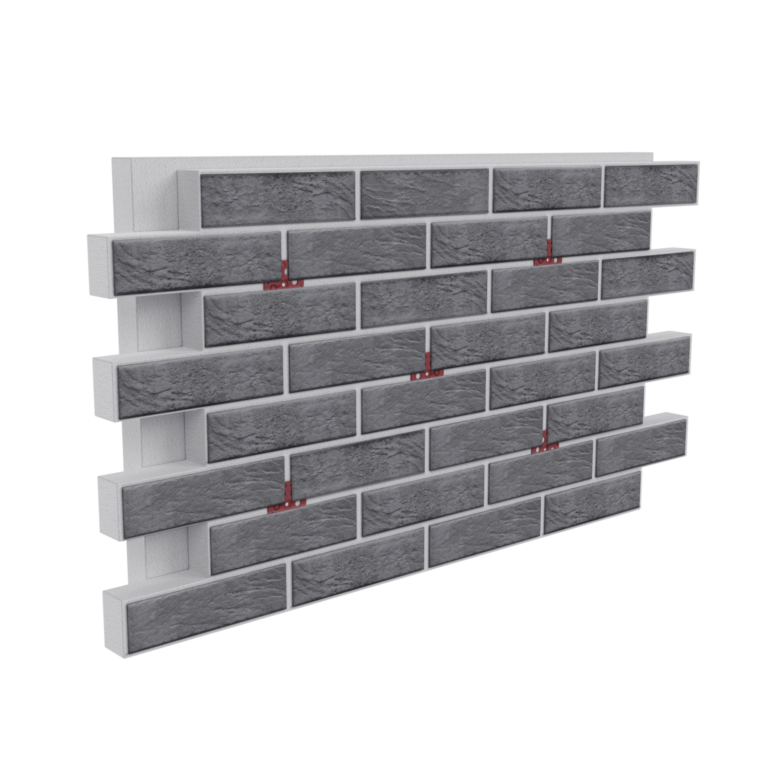

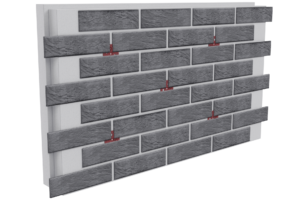

Thermal insulation boards for facades are monolithic structures that take into account the necessary level of thermal insulation, attractive appearance, and high quality of materials used during manufacturing. The manufacturer uses modern technologies that allow the use of thin bricks (same as clinker tiles) pressed into an insulation layer (XPS or EPS) with subsequent use of one-component polyurethane adhesive.

- ROYAL FACADE

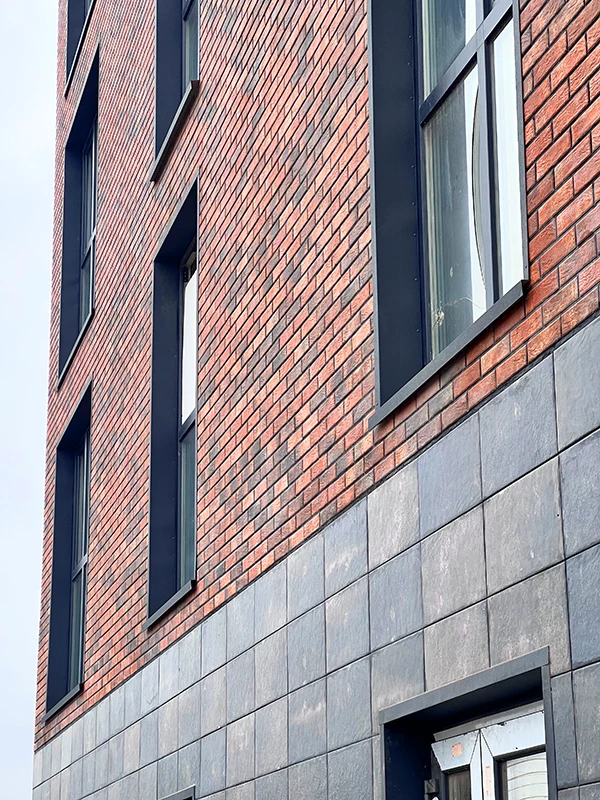

Real Examples of Our Insulation and Cladding Project

With the help of modern thermal insulation products with ceramic tiles of a certain design, you can easily solve the following problems in construction:

- Building energy efficiency guarantee

- Economical energy consumption

- Promoting eco-friendly choices through sustainable cladding solutions

- Quick, maximally simple installation

- Long service life

- Universal use of panels

- No need for seasonal work

- No need for regular facade maintenance

- ROYAL FACADE

Main Advantages of Insulated Curtain Wall Panels

There are many reasons to choose and buy clinker thermal panel. All reasons are related to a large number of undeniable advantages:

- Quality materials as the basis of each panel’s construction, guaranteeing high efficiency in insulating various buildings.

- Aesthetically attractive appearance: countless design options and shades are offered to choose from.

- Simple and quick panel installation. For maximum convenience when fixing the structure, the manufacturer provided 5 embedded elements made of high-strength plastic – washers.

- Long service life, resistance to mechanical damage and various weather conditions.

- ROYAL FACADE

Thin Bricks Insulation Board

The presented monolithic composite structure consists of tiles used as a decorative layer (clinker or ceramic). The tiles were pressed into the insulation material layer using a proven method – multiple pressing. Additionally, the manufacturer used one-component adhesive (polyurethane).

Convenient panel installation is now possible due to 5 washers (embedded plastic elements).

Anyone interested can familiarize themselves with our panel manufacturing process by watching the video on our YouTube channel

- ROYAL FACADE

Thin Brick Cladding

In manufacturing quality thermal insulation sandwich panel, we use facade Thin Brick Veneer – this can be ceramics, strong porcelain stoneware, or clinker. Our company works with products from Ukrainian and Polish brands:

Cerrad ![]() , Paradyz

, Paradyz ![]() , King Klinker

, King Klinker ![]() , Golden Tile 🇺🇦

, Golden Tile 🇺🇦

- ROYAL FACADE

Facade Thermal Panels Installation Process

All installation work should begin with thorough preparation of the facade surface. It’s important to eliminate any irregularities, serious damage, clean the surface of dust and dirt, and pre-dry it.

Thermal Board Cladding Stages and Recommendations from Royal Facade:

- Using a level, install the galvanized starting profile.

- Using special fastening elements, mark and install thin brick wall covering.

- Perform joint grouting using grouting mixture.

Once the installation of the facade cladding panels is complete, joint grouting can begin after 24 hours — giving the adhesive time to set slightly.

- ROYAL FACADE

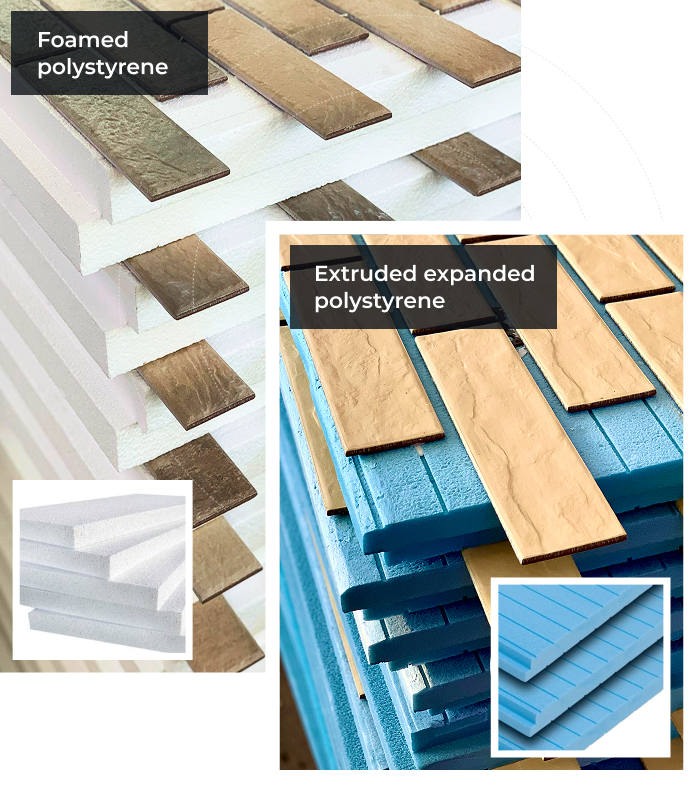

Types of Polystyrene: Expanded and Extruded

Royal Facade uses expanded polystyrene of our own production in manufacturing thermal barrier insulation sheets. This is a material with high density indicators. EPS thermal insulation composition includes flame retardants, eliminating the possibility of fire spread and support.

Extruded polystyrene is a product of Ukrainian brands. This material is considered moisture-resistant, strong, and known for its durability. Inert gases are used in the composition, making XPS thermal insulation an environmentally safe solution.

Both types of polystyrene belong to the list of high-quality insulation materials that are in special demand not only in the Ukrainian market but also abroad.

Thermal Panel Production – A Diverse Product Line:

Thin brick wall panels are offered in various formats:

– 32 tiles pressed into an insulation layer with quarter-locks located around the entire perimeter or horizontally.

– Panels with full decorative tile bonding or with tile edges partially extending beyond the insulation.Slope elements – uses 8 whole tile types with extruded polystyrene with standard 30mm thickness.

Cornice element – uses 8 whole tile types with a certain type of insulation, thickness ranging from 30-200mm.

Corner panels offered in various formats:

– 8 whole tiles and 8 halves connected to create a corner shape with decorative layer cut at 45/90 degrees.

– Additionally pressed into insulation layer with quarter-locks around perimeter/horizontally.

With full bonding/slightly protruding parts beyond polystyrene thermal insulationWall panel supplemented with large-format tiles (2-3 tiles per insulation layer depending on specific model). Such tiles were pressed on 90% of the panel surface, with a set of plastic washers for fixing the entire structure.

- ROYAL FACADE

Using Facade Panels: Economic Aspect

By choosing quality thin brick panel systems for facade insulation, every homeowner (or other building owner) chooses significant savings during winter heating season and summer air conditioning savings.

Special attention should be paid to calculations for selecting the necessary amount of materials. A calculation calculator is specially provided for this purpose. To order thermal panel with tiles, specify the following information:

- Specific building facade area

- Brand and shade of decorative layer (tiles)

- Set of fastening elements – their quantity and sizes

- Type of insulation material

- Optimal layer thickness

- Amount of adhesive foam

- Type, quantity, and corresponding shade of grouting mixture

The obtained information will allow the customer to learn about the final cost of thermal panels, their installation, and the total amount of all material for the facade isolation and insulation procedure.

Facade Thermal Panels: Types with "Brick-Look" Imitation Tiles

Large-Format Facade Thermal Panels

Straight element 23.6/5.9 in.

Straight element 23.6/6.9 in.

Straight element 23.6/11.8 in.

Straight element 23.6/23.6 in.

Straight element 31.5/6.9 in.

Straight element 35.4/5.9 in.

Straight element 35.4/6.9 in.

Large-format facade panels with 30x60 cm insulation layer

and Viano Antracite tiles

- ROYAL FACADE

Thermal Panel Varieties Based on Insulation Shape

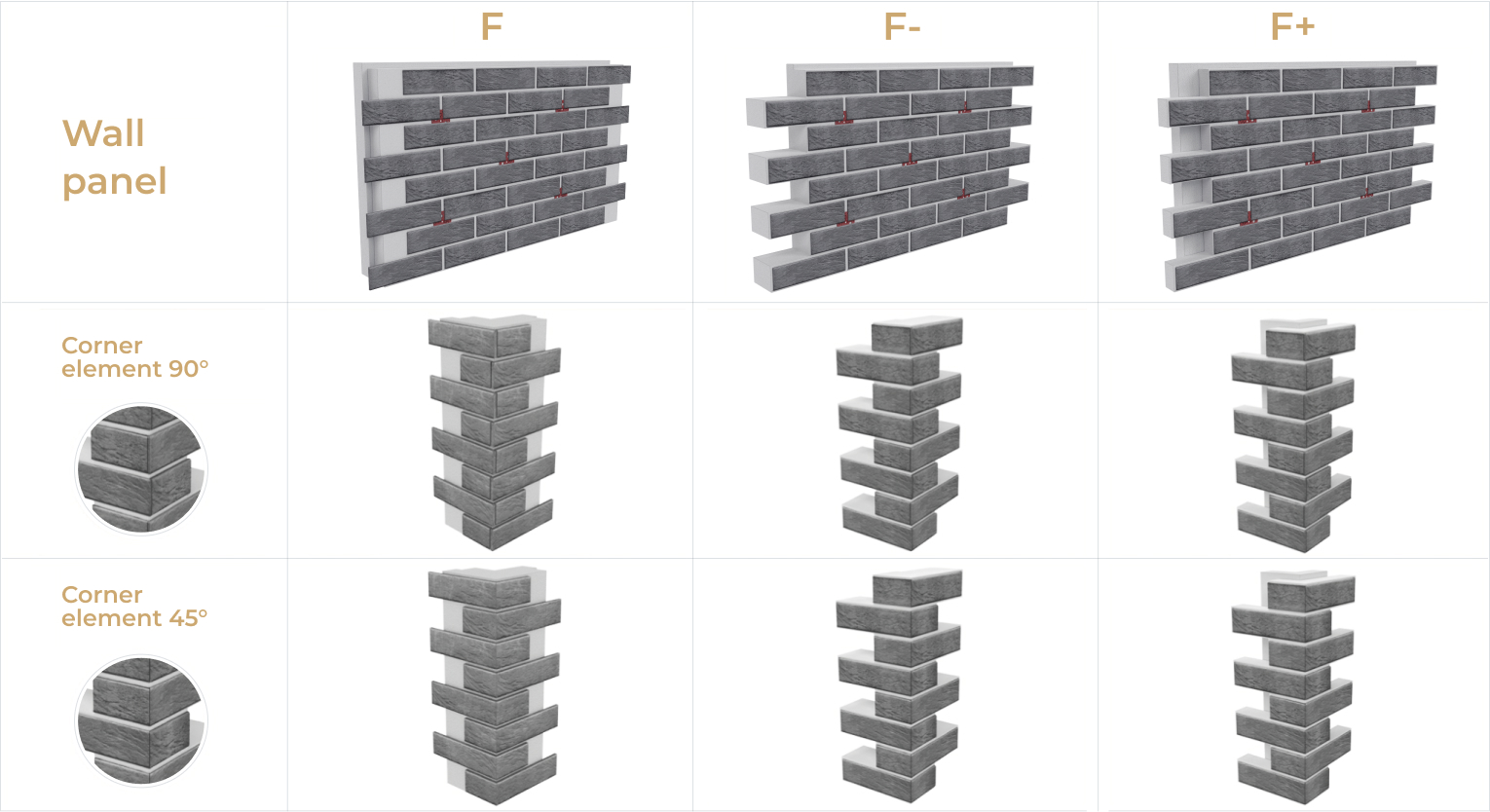

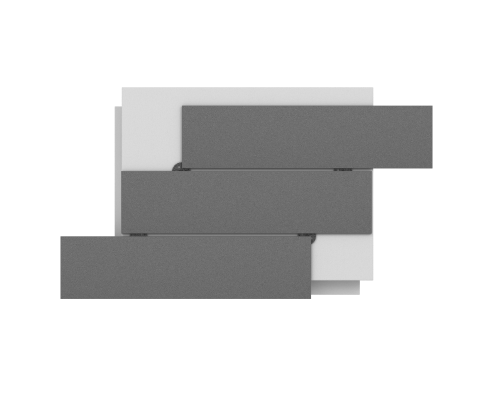

Based on this criterion, all Royal Facade™ panels are divided into several categories: F, F-, and F+.

Let’s examine each proposed type in detail:

F type

Format “F” insulation – these are thermal panels with clinker tiles, supplemented with a quarter-lock that eliminates cold bridge formation. Minimum thickness depends on the chosen insulation layer: for expanded polystyrene (EPS) – 1.97 in., for XPS thermal insulation board – 1.18 in.. Maximum thickness is the same for all insulation types – 11.81 in.

Main advantages of “F” type panels:

- Affordable cost

Versatility – this format is perfect for decorating and simultaneously insulating external surfaces - Reliable quarter-lock around the entire panel perimeter

- Tiles are almost completely pressed into the insulation layer (exception for particles protruding beyond insulation).

- According to Test Protocol №211-323/124/18, tile adhesion strength to insulation layer exceeds specified standards by 4.7 times.

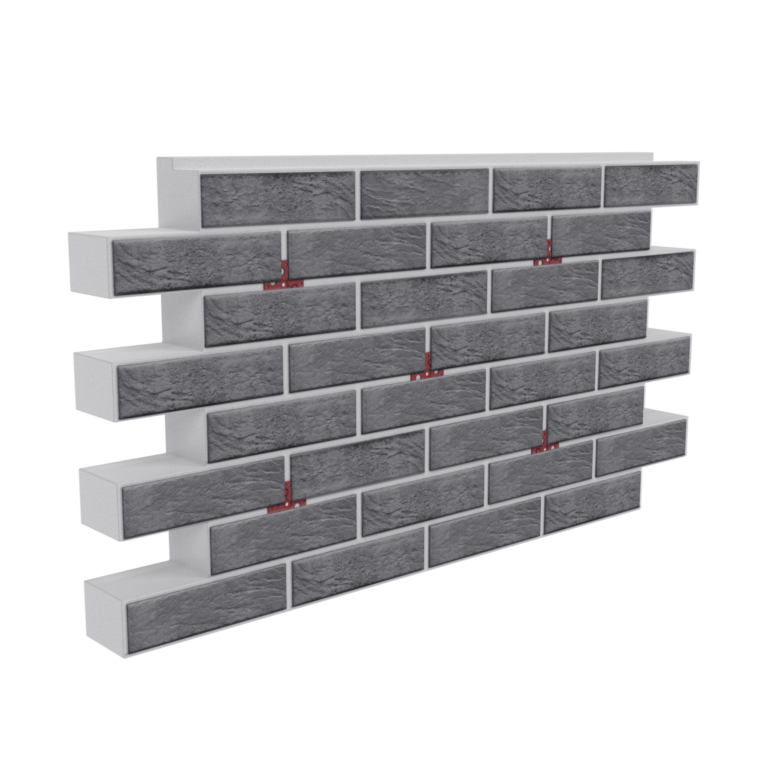

F- type

Format “F-” insulation – these are clinker thermal panels with quarter-lock located horizontally. Minimum thickness depends on chosen insulation layer: for expanded polystyrene (EPS) – 1.97 in., for extruded (XPS) – 1.18 in.

Maximum thickness is the same for all insulation types – 5.9 in.

Possible selection of most appropriate polyurethane thermal insulation thickness: 1.97 in., 3.15 in., 3.94 in., 4.72 in., 5.9 in. (corners up to 3.94 in.). This is an excellent solution for already insulated facades or perfectly level surfaces (pre-prepared).

Main advantages of “F-” type panels:

- Medium market price

- Simpler installation method for entire structure. However, additional foam application is needed in side connection areas due to quarter-lock use only horizontally

- Thin bricks/tiles completely pressed into insulation layer (according to Test Protocol №211-323/124/18, tile adhesion strength exceeds standards by 4.7 times)

- No cold bridge formation possibility horizontally. However, vertical locks remain unprotected (exception when special adhesive foam is additionally used)

F+ type

Format F+ insulation – these are clinker panels supplemented with quarter-lock for cold bridge protection and 100% surface tile bonding. According to Test Protocol №211-323/124/18, tile adhesion strength to insulation layer exceeds specified standards by 4.7 times.

Minimum panel thickness – 80mm. Available thickness options: 3.15 in., 3.94 in., 4.72 in., 5.9 in. (EPS and XPS). Maximum thickness is the same for all insulation types – 5.9 in..

In this case, quarter-lock is located around the entire facade structure perimeter. As a result, thin brick cladding results from bonding two identical insulation parts, ensuring perfect geometry. Additionally, the undesirable arch effect due to internal stress of the whole expanded form was avoided.

Main advantages of “F+” type panels:

- Cost of such panels is higher than the previous two formats – F and F-

- Full clinker tile bonding across the entire panel surface

- Maximally convenient and quick installation process

- Quarter-lock located around entire perimeter guarantees reliable cold bridge protection, eliminating the need for additional adhesive foam use at thermal panel joints

- ROYAL FACADE

Thermal Panel Dimensions

All Royal Facade™ brand products can be called a universal solution for reliable polystyrene facade isolation – decoration and insulation of external walls for various buildings:

- Private houses

- Office buildings

- Shopping and entertainment centers

- Hotels

- Cottages

- Utility buildings

As a result, you can insulate styrofoam facade regardless of what materials were used in construction.

Thanks to Royal Facade company capabilities, any dream can become reality!

ROYAL FACADE

Don't postpone the opportunity to order quality thermal panels today!

- ROYAL FACADE

Facade Thermal Insulation Boards vs Other Popular Facade Materials

The huge consumer demand for special facade thermal boards is gradually increasing without slowing down. Important features and main differences of such materials include the ability to install in any season and perform facade cladding of various buildings. The versatility of thin insulation board is also manifested in facade material – boards are suitable for different external surface materials.

To avoid mistakes and order truly appropriate board types, you need our specialist’s support. We’re ready to perform all preliminary calculations, helping determine the type and optimal thickness of XPS thermal insulation board or EPS thermal insulation. When making a selection, current energy efficiency legislation standards must be considered, referring to the specific region where the building is located.

- ROYAL FACADE

FAQ

Detailed answers to the most popular customer questions about material selection, installation work, and Royal Facade company operating principles

Clinker thermal panels are a universal solution for every house and any other building. Their use simultaneously guarantees reliable thermal insulation, facade protection from mechanical damage and negative atmospheric impacts, and preserves attractive facade design. Additionally, any decorative layer can be selected – shade and design.

The simple and understandable panel design guarantees quick installation and the possibility of completing the entire process yourself. Despite installation work simplicity, preliminary consultation from our specialist team is essential. Our specialists are ready not only to answer customer questions but also offer professional installation services. In this case, you can properly evaluate all facade structure advantages, considering main fixation nuances and external surface preparation rules.

Thermal panel installation cost depends on many nuances and certain factors. For quick calculation, use our special calculator considering: building facade area; insulation type and thickness; tile brand and shade; number of bags and grouting mixture color; fastening element type, quantity, and size; number of adhesive foam cans. Therefore, it’s difficult to specify exact cost without individual calculations. Depending on each customer’s wishes and requirements, we can select the most appropriate solution based on allocated budget.

These panels are often called universal since they can be used for various buildings. Thermal panel application is especially useful for buildings requiring quality external wall thermal insulation, wall leveling, and quality decorative finishing based on exterior design. The main thing is remembering the need for preliminary surface preparation.

Facades with thermal panels don’t require complex maintenance. For example, when dust or dirt appears on the facade surface, use a cloth – dry or damp. With green coating and moss appearance, use special products that can be applied to the facade with a brush or sprayer. After this, tiles should be washed with water.